High power directional couplers let you monitor, measure, and control RF signals in transmitter systems without losing much power. These four-port passive devices sample a small fraction of your signal while letting most of it pass through to your load.

In defense and commercial transmitter applications, reliable RF power sampling is not optional. Systems like radar, electronic warfare (EW), SATCOM ground stations, broadcast transmitters, and communications infrastructure all depend on knowing exactly how much power they are sending out.

If your transmitter output drifts or fails, you need to catch it fast. That is where these couplers become your first line of protection.

This guide covers how high power directional couplers work in transmitter applications, what specs matter most for defense systems, and how to pick the right coupler for your program requirements.

How Directional Couplers Work in Transmitter Systems

A directional coupler sits between your transmitter and antenna. It samples the signal traveling in one direction on your transmission line while ignoring signals going the other way. This makes it a perfect signal monitoring coupler for checking forward power and reflected power separately.

The coupler has four ports:

- Input port where power enters from your transmitter

- Output port where power exits to your antenna or load

- Coupled port where a small sample of the signal appears for measurement

- Isolated port which stays quiet unless reflected signals return from your load

Your main RF signal enters the input port and exits through the output port with very little loss. A small amount of that signal couples to the coupled port, where you can connect a power meter or feedback circuit. The isolated port stays quiet unless there is a reflected signal coming back from your load.

For transmitter applications, this separation matters because you often face changing load conditions. Antenna impedance can shift based on scan angles, environmental factors, or system faults.

A broadband directional coupler with high directivity tells you exactly what is happening in both directions. This information helps you protect expensive amplifier hardware and keep your system running at peak performance.

Why High Power Matters for Defense Transmitters

Military radar and EW RF components often run at power levels from hundreds of watts to tens of kilowatts. Standard low-power couplers cannot handle these loads. They will either burn up or drift out of specification under stress.

High power directional couplers solve this problem through better materials and construction. All-metal designs with air dielectric configurations offer superior temperature stability. Rugged ferrite construction is often chosen for shock, vibration, and thermal cycling conditions common on military platforms. These design choices let the coupler handle continuous high power operation without degrading over time.

Key specifications to evaluate include:

- Power handling (average and peak): Your coupler must handle your continuous transmit power plus any peak pulses. Defense radar systems often run pulsed modes with peak powers much higher than average. Check both ratings carefully before selecting a model.

- Insertion loss: Every decibel of loss in your main line means less power reaching your antenna. Low insertion loss keeps your system efficient. Quality couplers deliver less than 0.5 dB insertion loss across their operating bandwidth.

- Directivity: This tells you how well the coupler separates forward and reverse signals. Higher directivity means more accurate power measurements. For precision RF power sampling in defense systems, look for directivity of 20 dB or better.

- Frequency range: Your coupler must cover your transmitter’s operating band with flat coupling across the range. Broadband models spanning multiple octaves give you flexibility for multi-band systems and future upgrades.

- VSWR: Low voltage standing wave ratio at all ports minimizes impedance mismatch errors and improves measurement accuracy. Aim for VSWR below 1.25:1 for best results.

Commercial Transmitter Applications (Where High Power Couplers Matter)

High power directional couplers are also common in commercial transmitter systems where uptime and stable performance matter. In the SATCOM ground infrastructure, couplers support forward and reflected power monitoring to protect high power amplifiers and verify output under changing load conditions. In broadcast and communications infrastructure, they help teams confirm transmit power levels, spot drift early, and support remote health checks during continuous operation.

In test and measurement and production test, a coupler can provide repeatable RF power sampling for calibration, validation, and troubleshooting without interrupting the main line. Across these use cases, the same selection logic applies: match average and peak power handling, confirm flat coupling across the band, and choose connectors that support your frequency and power without overheating.

Quick Reference: Key Specifications for Defense Transmitter Couplers

| Specification | Target Value | Why It Matters |

| Power Handling (Avg) | Match system power + 20% margin | Prevents thermal damage during continuous operation |

| Power Handling (Peak) | Match pulse power requirements | Handles radar pulse modes without breakdown |

| Insertion Loss | Less than 0.5 dB | Maintains transmitter efficiency |

| Directivity | 20 dB or higher | Provides accurate forward/reverse measurements |

| VSWR | Below 1.25:1 | Reduces impedance mismatch errors |

| Frequency Range | Cover full operating band | Supports multi-band and frequency agile systems |

Electronic Warfare Applications

Electronic warfare systems place extraordinary demands on RF components. These platforms must detect, analyze, and counter threats across wide frequency ranges while operating in harsh field conditions.

In IEEE Spectrum, Bryan Clark, expert in electronic warfare, explains that EW is a pivotal part of modern warfare because forces rely on radios, radars, and infrared sensors and use EW to control the spectrum, protecting their own sensing and communications while denying access to an opponent.

That mission puts real pressure on transmitter chains. Output power has to stay within spec, faults need to be detected fast, and hardware must keep working under harsh conditions.

For EW transmitter applications, high power directional couplers serve several key functions:

- Transmit power monitoring keeps your jammer or countermeasure system operating at specified output levels. If power degrades, detection range suffers. Continuous monitoring through the coupled port feeds your system controller so it can respond to any changes.

- Reflected power protection prevents amplifier damage when antenna impedance shifts during operation. Steered array antennas change their impedance across scan angles. Your coupler catches dangerous reflected power before it harms your transmitter.

- Frequency agile support requires couplers that perform consistently across wide bandwidths. Multi-octave broadband directional coupler designs maintain flat coupling from low frequencies through microwave bands. This matters for systems that must hop frequencies or cover multiple bands.

The EW market continues to grow fast. Defense contractors need RF component suppliers who understand these demanding applications and can deliver products that meet strict military requirements.

Selecting the Right Coupler for Your Program

Defense procurement teams should consider several factors beyond basic specifications:

Connector options

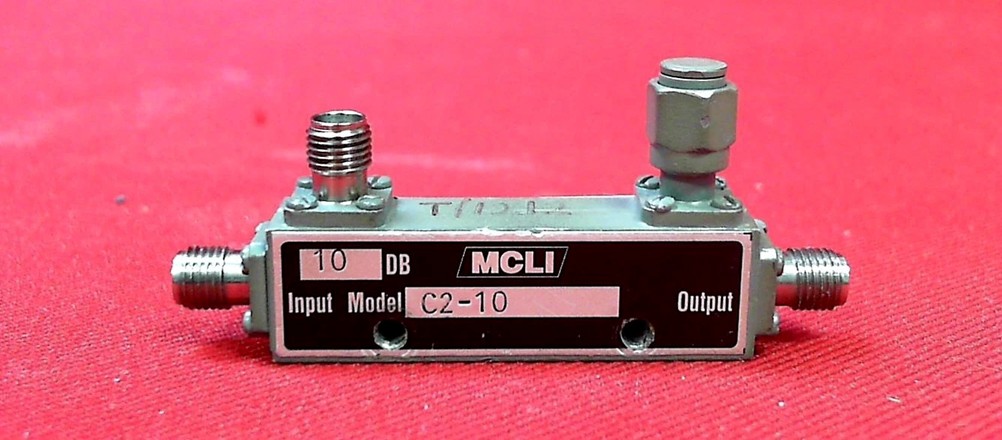

Standard connectors like Type N and SMA work for most applications. High-power systems may need larger connectors like 7/16 DIN to handle current without overheating. Match your connector choice to your power level and frequency range.

Form factor

Space and weight matter on airborne platforms. Compare package sizes between vendors. Some high-power couplers achieve compact dimensions without sacrificing performance. This can make a real difference in tight installations.

Lead time and availability

Production schedules cannot wait months for custom parts. Check stock availability for standard models. Many configurations ship within days from established suppliers. In-stock inventory reduces your program risk.

Custom capabilities

Specialized requirements may need modified designs. Verify your supplier can adjust frequency ranges, coupling values, or mechanical configurations to match your system needs. Look for manufacturers with engineering support who can help you find the right solution.

Quality certifications

Defense programs require documented quality processes. ISO 9001:2015 certification demonstrates controlled manufacturing and consistent product performance. Ask about testing procedures and quality documentation.

Technical support

Complex transmitter systems benefit from supplier expertise. Choose a manufacturer who can help with specification matching, system integration questions, and application guidance. This support becomes valuable when you face unexpected challenges.

Moving Forward With Your Transmitter System

Choosing the right high-power directional coupler protects your investment in transmitter hardware. The right coupler gives you accurate power measurements, early warning of system problems, and confidence that your platform performs as designed.

Defense contractors working on radar, EW, or communications systems should evaluate coupler specifications against their specific operating conditions. Power levels, frequency ranges, environmental requirements, and space constraints all drive your final selection. Taking time to match these factors to available products pays off in system reliability and reduced maintenance costs.

To discuss your transmitter application requirements and get technical guidance on coupler selection, contact us for specification matching support.

MCLI offers 38+ years of experience manufacturing precision RF microwave components for defense, aerospace, and commercial applications, with many high-power models in stock for fast delivery.