Wireless medical devices live or die on clean, steady signals. If you’re asking, “What are RF components?“, you’re really asking how those devices keep a safe link in busy hospital airwaves.

In a few minutes, you’ll see how the core RF parts work together to cut noise, prevent dropouts, and support safer care.

You’ll get a quick tour of the key parts, the risks they address, and simple, early design checks your team can use to build confidence before testing.

What Are RF Components in Modern MedTech

RF components are the building blocks that help medical devices send and receive data wirelessly. They include amplifiers, filters, antennas, oscillators, and couplers. Each one plays a unique role in maintaining a stable signal and preventing cross-talk between systems.

In medical settings, this reliability isn’t optional. Devices that use radio frequencies must operate in environments filled with other electronic signals. This includes hospital Wi-Fi and diagnostic equipment.

A well-designed RF system keeps communication clear and prevents potentially harmful interference.

Common RF Components Used in Medical Devices:

- Antennas – transmit and receive wireless signals efficiently.

- Filters – remove unwanted noise and maintain signal clarity.

- Amplifiers – strengthen weak signals for accurate data transmission.

- Oscillators – create consistent frequency outputs to maintain connection stability.

- Couplers – help measure and control signal power.

These components work together to create medical devices that perform reliably. Even in the most complex hospital or home-care environments. A well-integrated RF design means safer operation for both the patient and the provider.

Why RF Design Matters for Medical Device Safety

When a device transmits patient data, accuracy and timing are everything. An unstable RF connection can delay alerts, misread vitals, or interrupt therapy delivery. For patients depending on real-time monitoring, that’s not just an inconvenience. It’s definitely a safety risk.

Regulatory bodies like the U.S. Food and Drug Administration (FDA) require medical device manufacturers to test for electromagnetic compatibility (EMC). This is to confirm that RF signals don’t cause harmful interference.

Poor EMC design can lead to device malfunction or data loss, which can affect clinical outcomes.

RF design also impacts patient safety by:

- Reducing interference: Filters and shielding help separate medical device signals from surrounding equipment.

- Improving accuracy: Stable RF signals transmit patient data precisely as measured.

- Meeting compliance: Tested and validated RF systems help manufacturers achieve global regulatory standards.

Reliable RF performance protects not just the signal. It protects the patient.

How a Valuable Attenuator Supports Safer Wireless Design

When medical devices send or measure RF signals, level control matters. A variable attenuator rf helps set clean, safe signal levels during:

- design

- verification

- and even in-field diagnostics

That way, links stay stable and measurements stay honest.

Attenuators reduce power to prevent overload. It can also improve impedance matching, and widen a system’s usable range. These are small moves that pay off in safety and reliability.

They are also used to reduce signal levels, improve matching, and measure gain/loss across the signal chain. This is exactly what teams need when checking wireless performance in busy clinical spaces.

Analog Devices adds that attenuators help balance levels, extend dynamic range, and support calibration. It keeps tests repeatable from prototype to production.

Where attenuators add immediate value:

- Protect test gear and DUTs. Avoid front-end overloads and distortion while characterizing transmit paths and receivers. (Even spectrum analyzers place an RF attenuator up front to prevent mixer overload.)

- Tighten impedance matching. Trim level and reflection to keep radios talking cleanly. This reduces retries and dropped packets during evaluation.

- Make compliance work smoother. Stable, known attenuation steps help teams run EMC-oriented checks more repeatably as they prepare for standards like IEC 60601-1-2 referenced by the FDA’s EMC guidance.

When used well, a valuable attenuator becomes a simple safety multiplier: fewer overload surprises, cleaner data, and faster confidence before formal testing. Keep one in the plan early, and your wireless path will be easier to tune as the design matures.

How Medical Device Teams Choose Reliable RF Components

Selecting RF components isn’t only about signal strength. It’s about ensuring safety, efficiency, and compliance. Design choices made early in development matter. They can affect everything—from getting device approval to achieving market success.

Key RF Parameters to Evaluate:

- Frequency range: Determines how well the device communicates in different settings.

- Power handling: Ensures the signal remains consistent without overheating.

- Size and form factor: Critical for portable or implantable devices where space is limited.

- Material quality: Affects performance, longevity, and biocompatibility.

Medical device teams gain more when they work with RF specialists. These experts understand both the technical details and the regulatory challenges of wireless healthcare. Partnering early in the design phase reduces the risk of late-stage redesigns or compliance failures.

A well-chosen RF component helps build trust. Not only between engineers and regulators. But also between devices and the patients who depend on them.

Real-World Examples of RF Components Improving Safety

RF design isn’t just theoretical. It’s saving lives every day. Consider a wireless glucose monitor. Without a reliable RF link between the sensor and the insulin pump, a communication error could cause a dangerous insulin dose delay.

The same is true for cardiac monitoring devices. They rely on steady RF signals to alert healthcare providers when a heartbeat becomes irregular.

From handheld scanners to wearable biosensors, the common thread is safety through stable communication. RF components transform patient data into real-time, dependable insights.

Building Trust in Wireless MedTech Through RF Expertise

Every medical device manufacturer wants their products to be trusted in hospitals, clinics, and homes. That trust begins with reliable communication—and reliable communication depends on RF integrity.

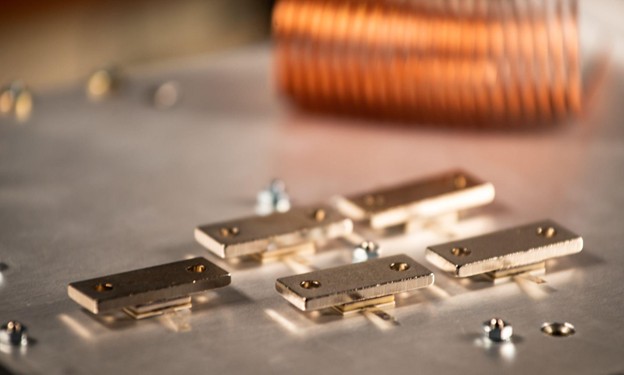

MCLI has spent decades helping manufacturers design RF and microwave components. These are manufactured not only for the sake of providing RF products. But they also meet strict safety and performance standards.

By understanding the demands of modern MedTech, MCLI helps teams build safer wireless innovations. The support continues from early prototypes all the way through full production.

If you’re a medical technology professional exploring new wireless designs, now is the time to learn more. Explore RF design partnerships, testing resources, and compliance-ready solutions. These can help make your next medical device both safe and connected.

Discover how MCLI enables medical device manufacturers to integrate safe, high-performance RF systems. Learn more about MCLI’s RF expertise.